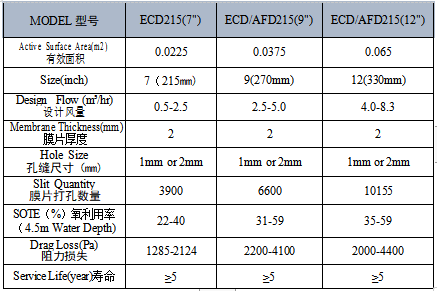

MODEL:ECD-P

Size(inch): 215/270/330mm

Active Surface Area(m2):0.0225/0.0375/0.065

Design Flow (m³/hr): 0.5-8.3

Membrane Thickness(mm): 2

Hole Size: 1-2mm

Slit Quantity: 3900-10155

SOTE(%)(4.5m Water Depth): 22-59

Drag Loss(Pa): 1285-4400

Service Life(year): ≥5

We manufacture our disc diffusers with compression molded membranes.Standard materials are EPDM and fluoroelastomer layered EPDM.There is an art to using just the right amount of plasticizer in an EPDM membrane. Use too much, or the wrong type, and emulsifying fats can leech plasticizer and cause shrinkage and increase hardness. Use too little, and the rubber loses its memory, bubble size increases, and the membrane is at risk for flexure failure. SSI has had a great deal ofexperience experimenting with different types and amounts of plasticizer, as well as other components of formulated EPDM rubber, such as fillers and curatives, and we put this experience to work.SSI uses a specially shaped tool to punch holes in the diaphragm from the inside out.This minimises the size of the holes in the diaphragm surface. Through specialised synthesis and surface treatment techniques, we are able to machine smooth holes in hydrophilic surfaces, checking the uniformity of the perforation depth of each diaphragm to ensure uniform air release, and quickly release small air bubbles as small as 1-2mm in diameter.

Single mold technology to reduce costs.

Available in 4 versions:7",9", 12" and 20".

3/4" M NPT connection

High efficiencies(SOTE) and low pressure drops tested according to ASCE standards.

High resistance environmentally friendly polypropylene lend body(100℃).

Membrane with low plasticzer content to minimize the phenomena of loss of elasticity and shrinkage.

Contact: Miss.Amber

Phone: 0086-18019736003

E-mail: amber@shdubhe.com

Whatsapp:0086-18019736003

Add: Room 428, No.255 Xinjinqiao Road, Pudong District, Shanghai, China

We chat