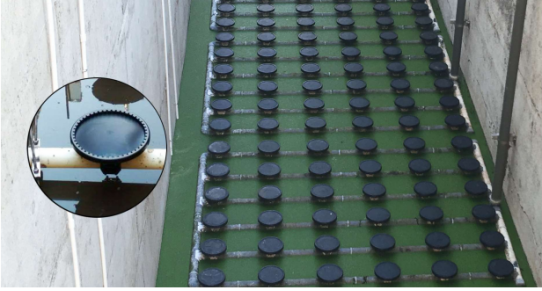

EPDM is a synthetic rubber product developed according to the customer's usage requirements. Due to its unique compound composition and compression moulding process, the membrane retains its physical properties for long periods of time under minimal water pressure, resists tearing, and retains its shape after years of cyclic operation, producing fine air bubbles. Our EPDM membrane products have been tried and tested in a variety of municipal and industrial wastewater treatment applications with excellent results. However, standard EPDM is not recommended for applications where solvents, grease, or oils are present, as well as high concentrations of metal salts.

Manufactured using a compression moulding process with uniform specific gravity and thickness. Resistant to pulling in various directions and to changes in the properties of the diaphragm material. High coefficient of elasticity, proper taper can reduce unit pressure, low pressure loss, high dissolved oxygen efficiency, long service life.

The centre area of the diaphragm is non-porous and the diaphragm will fall back to the base and seal when the aeration system is shut down. The entire diaphragm surface allows good air passage. Membrane resists clogging and is at least 70% hydrophilic.

Tear elongation of up to 700% is suitable for processes with cyclic opening and closing operations and retains its shape over long periods of time, producing fine air bubbles. The diaphragm material is high quality EPDM rubber with less than 12% oil content. The characteristics are as follows (attached table):

Schedule: EPDM diaphragm performance parameters

Item | Criteria | Unit | Values |

Hardness | ASTM D2240-95 | 邵尔A | 60 |

Tensile strength | ASTM D412-92 | N/mm2 | >2000 |

Tear strength | ASTMD624-91,Die T | N/m | >110 |

Permanent deformation at 100% elongation | ASTM D412-92 | % | <5% |

Maximum elongation at tear | ASTM-D412-92 | % | 600 |

Ozone Resistance(70 hours, 40º C, 50mPa partial ozone pressure, no decomposition) | ASTM D1171-94 | - | eligible (voter etc) |

UV resistance | - | - | Qualified |

Hot air ageing resistance(70 小时 , 70º C) | ASTM D573-88 | - | Tear strength change rate <3% |

- | Change in tearing elongation <25% | ||

- | Hardness change <5 degrees | ||

Rate of change of deformation in compression(22 小时, 70º C) | ASTM D573-88 | % | <20 |

Liquid Resistance, Volume Change(水,70 小时, 100º C) | ASTM D471-94 | % | <3 |

Low Temperature Resistance (-40º C, non-crisp) | ASTM D832-92 | - | Qualified |

Attached:Membrane material composition table

Polymer | 58% |

Carbon Black | 17.5% |

Plasticisers | 19% |

Others | 5.5% |

2. Introduction to the performance of EPDM membrane coated with PTFE and VITON.

PTFE (polytetrafluoroethylene) E and VITON are synthetic rubbers commonly known as fluoroelastomers. They have a wide range of resistance to a variety of chemicals, solvents, oils, greases, etc. that can cause damage to conventional rubber, and are therefore recognised as a material with excellent performance. However, the disadvantage is that they are expensive. So SSI developed the application of fluoroelastomer coatings, a patented method of permanently bonding to EPDM surfaces or other substrates, which has proven to be a proven method. SSI's new technology allows the diaphragm to not only maintain the excellent physical properties of traditional rubber materials, but also to provide the chemical, solvent, and grease resistance of the world's highest-grade rubber materials, at a cost you can afford. You can afford it. SSI's new fluoroelastomer-coated EPDM diaphragms have been proven to be free of scaling and any change in material properties in many wastewater treatment plants that have experienced diaphragm damage due to calcium build-up and solvent corrosion.

Table: PTFE membrane performance parameters

Item | standard | Unit | value |

Hardness | ASTM D2240-95 | 邵尔A | 60 |

Tensile strength | ASTM D412-92 | N/mm2 | >2000 |

Tear strength | ASTMD624-91,Die T | N/m | >110 |

Permanent deformation at 100% elongation | ASTM D412-92 | % | <5% |

Tearing elongation max. | ASTM-D412-92 | % | 700 |

Friction System ( | 0.09 | ||

Ozone Resistance(70 hours, 40º C, 50 mPa partial ozone pressure, no decomposition) | ASTM D1171-94 | - | eligible (voter etc) |

UV resistance | - | - | eligible (voter etc) |

Hot air ageing properties(70 小时 , 70º C) | ASTM D573-88 | - | Change in tear strength <3% |

- | Change in elongation at tear <25% | ||

- | Change in hardness <5 degrees | ||

Rate of change of deformation in compression(22 小时, 70º C) | ASTM D573-88 | % | <20 |

Liquid Resistance, Volume Change(水,70 小时, 100º C) | ASTM D471-94 | % | <3 |

Low Temperature Resistance (-40º C, non-crisp) | ASTM D832-92 | - | eligible |

Almost universal solvent resistance (except toluene and MEK) | |||

Almost universal enlightenment resistant to chemicals (except chlorine trifluoride and molten alkali metals) | |||

Almost 100% resistant to ageing (PTFE specimens exposed to different climatic conditions for 20 years without any change in physical properties). | |||

3.Material comparison

4. About the performance advantages of PTFE

Developed in 2004 by SSI Patents, PTFE coated EPDM membranes are proven technology. Since the introduction of PTFE membranes, SSI's patented technology has made tremendous strides in reliability, cost and efficiency, and aeration system monitoring, allowing you to keep your plant running at peak operating conditions 24/7, 365 days a year.

SSI's patented PTFE membranes are more durable than ordinary EPDM membranes and are becoming the industry standard worldwide.

SSI's PTFE membranes are used in a wide range of municipal and industrial applications including dairies, pulp and paper, beverage and refineries. Since 2004, SSI's PTFE membranes have been proven to provide improved scale protection, resulting in fewer cleanings in most cases 5 to 10 times better performance than standard EPDM membranes made by the industry's leading manufacturers.

PTFE has replaced silicone and polyurethane membranes.

5. PTFE properties

Ø Resistance to biofouling and chemical precipitation

Ø Creep resistance

Ø Resistance to plasticiser loss

Traditional EPDM membranes have a short life in pulp and paper mills due to fouling, creep (stretching) and plasticiser loss (shrinkage). SSI's PTFE membranes can help your mill run longer, reduce downtime and improve oxygen transfer efficiency. PTFE membranes are a small investment that can keep your mill running for years before the next membrane replacement or blower failure.

In independent studies, SSI's PTFE membranes have shown less plasticiser migration and slower creep than other materials. Maintenance of the plasticiser in SSI's PTFE membranes allows the membranes to maintain their initial properties, helping to preserve the performance and efficiency of your aeration system.

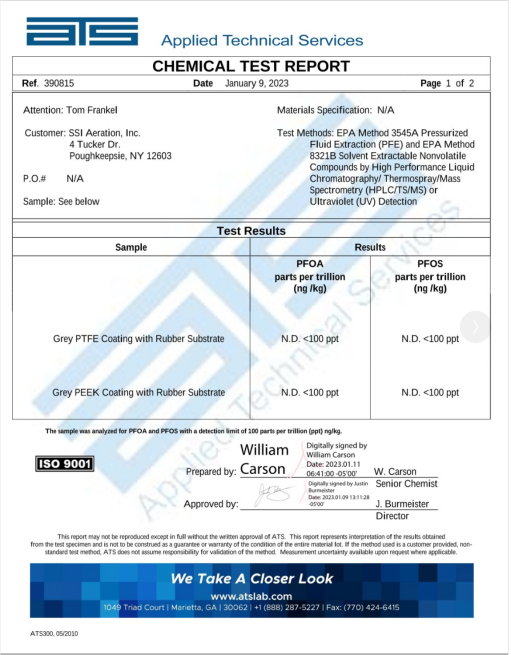

6.PTFE test report

SSI PTFE and PEEK coated diffusion films do not contain PFAS or PFOA.

When SSI worked with suppliers to develop coatings in the 2000s, SSI insisted on coating packages that did not contain heavy metals or by-products that could theoretically be used in potable water service, even if our products were used in wastewater.

Contact: Miss.Amber

Phone: 0086-18019736003

E-mail: amber@shdubhe.com

Whatsapp:0086-18019736003

Add: Room 428, No.255 Xinjinqiao Road, Pudong District, Shanghai, China

We chat