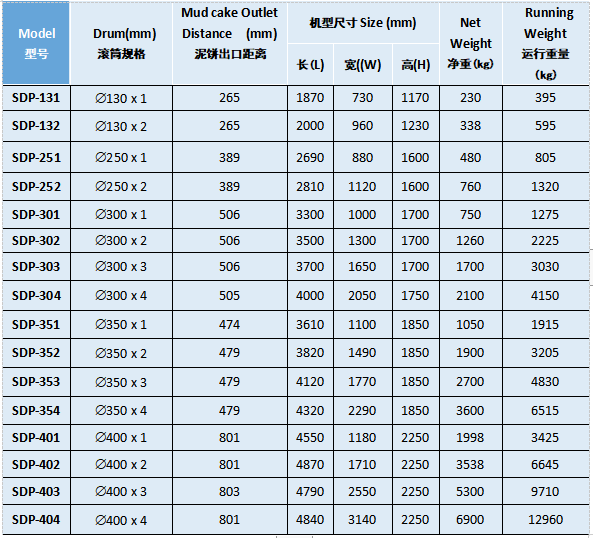

Drum: 130 x 1-400 x 4

Mud Cake Outlet Distance (mm):265-801

Net Weight(kg):230-6900

Running Weight (kg):395-12960

Washing water volume(L/h) :43-460

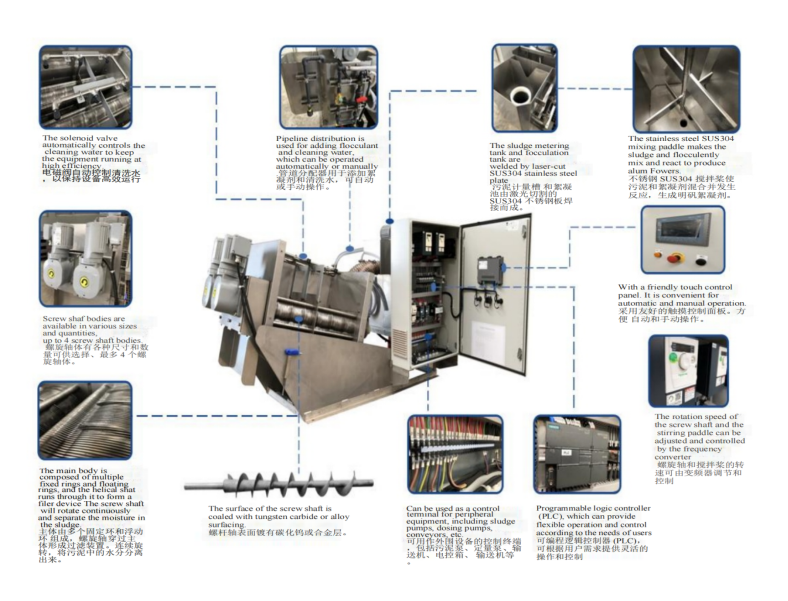

Our produces and manufactures the screw type sludge dehydrator, at present, has formed a variety of specifications and models series to meet dif fferent sludge treatment capacity and different needs of customers.

The double screw sludge dewatering machine integrates the automatic control cabinet and sludge concentration and dehydration body with liquid tar nk. It can realize high-efficiency flocculation under the condition of full automatic operation, and contin huously complete sludge concentration and pressing dehydration, and finally return or discharge the collected filtrate.

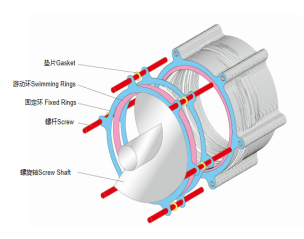

The main body of the stacked screw sludge dewatering machine is composed of multiple fixed rings and swimming rings, and the screw shaft runs through it to form a filtering device.

The front section is the concentration section, and the back section is the dehydration section, which completes the sludge concentration and dehydration in one cylinder, and replaces the traditional filter cloth and centrifugal filtration methods with a unique and subtle filter pattern.

nThe process is simple, sludge dewatering is efficient and energy-saving, and the system investment is small.

nThe system can be programmed to make the operation convenient and accurate.

nUnique flocculant makes sludge dewatering easier.

nThe dispensing is uniform and accurate, and the operation cost is saved.

When the equipment is running, the sludge is pushed from the inlet to the filt barrel by the spiral spindle and moves to the discharge outlet. As the pitc h between the spiral spindles decreases gradually, the pressure on the sludge increases continuously, and under the action of pressure difference, the sludge begins to dehydrate, and the filter gap between the water fixing plate and the movable plate flows out. When the equipment relies on the self-cleaning function between the fixed plate and the movement, the clearance of the filter can be cleaned to prevent clogging, and the mud cake is discharged from the discharge outlet under the propelling action of the screw shaft after full dehydration.

The main body of the stacked screw sludge dewatering machine is composed of multiple fixed rings and swimming rings, and the screw shaft runs through it to form a filtering device.The front section is the concentration section, and the back section is the dehydration section, which completes the sludge concentration and dehydration in one cylinder, and replaces the traditional filter cloth and centrifugal filtration methods with a unique and subtle filter pattern.

Contact: Miss.Amber

Phone: 0086-18019736003

E-mail: amber@shdubhe.com

Whatsapp:0086-18019736003

Add: Room 428, No.255 Xinjinqiao Road, Pudong District, Shanghai, China

We chat